Model LAM900 - The Mill of Cereals

This mill is an our production and has been realized using 2 cylinders obtained by iron forged hardened.

-

Most popular related searches

Details

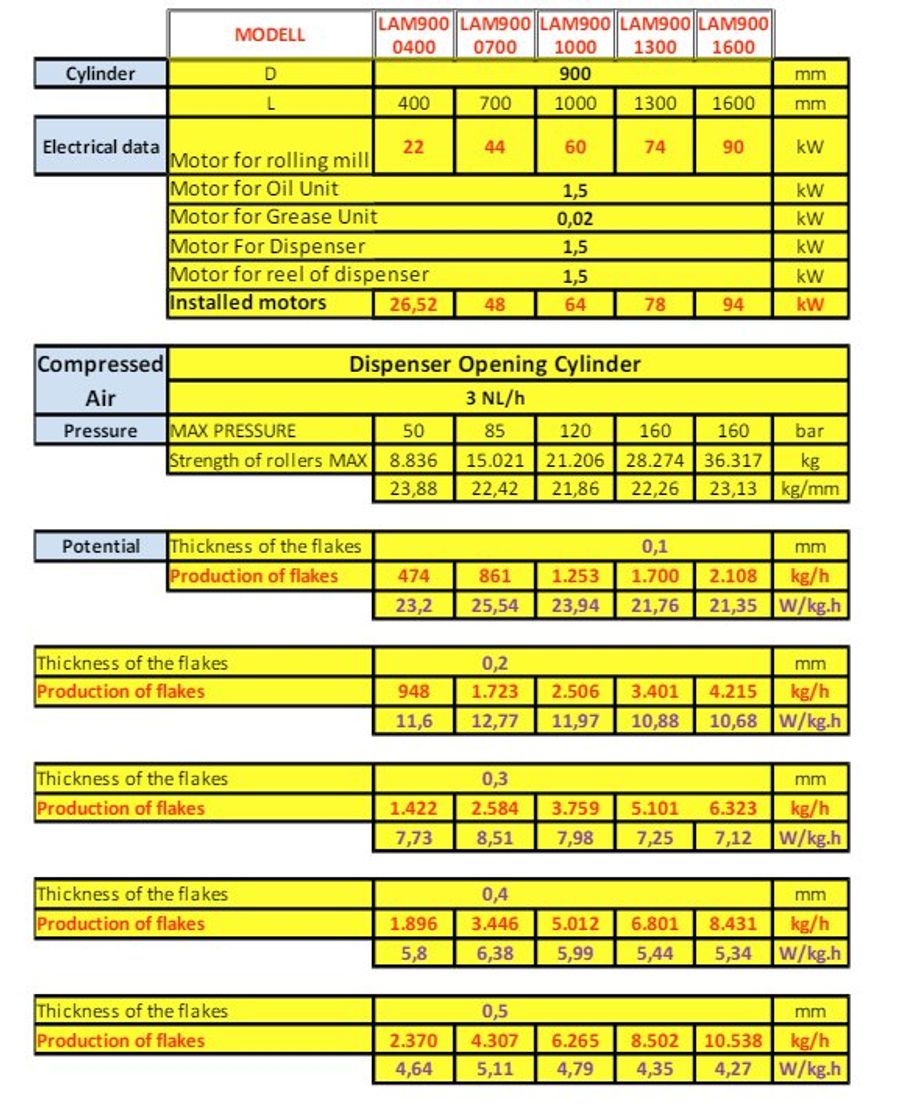

- With a thickness of 0. 1 and a gelatinization of about 100% produces the semolina pasta (corn or rice)

- With a thickness of 0.2 and a gelatinization of about 90% is produced the semolina or coveted for instant polenta

- With a thickness of 0.25 and a gelatinization of about 85% is produce flakes for cattle

Cereals are stabilized with a maximum humidity of 14% for storage for a year (humidity higher than 14% can lead to mold after a few days).

The large diameter of the cylinders has been chosen equal for all models of Thermo-Flaked series ''LAM900'', as obtained from a precise calculation that evaluates the cone formed between cereal and steel and the tightening angle between the two cylinders (Nippel angle), previous crushing, variable decreasing with the increase of the diameter.

Nippel Angle

The processing of cereals, with these cylinders of large diameter, allows a regular production in the absence of problems of poor performance or production of non-regular due to the sliding of the grain between the rolling cylinders. In this way it is possible to guarantee Hourly productions, both for processes of individual grains that for productions of mixed grains (barley, maize, pellets,…).

The cylinders are supported by two shafts in special steel hardened high resistance, largely oversized to give the machine greater reliability, without any kind of welding (since the welding techniques applied to this group, would lead to breakage due to phenomena of fatigue). On these shafts are mounted two pairs of bearings to double rows of rollers oscillating, forced to hot, which are housed in special massive media obtained from iron castings (designed and realized in our plant). A cylinder is made integral with the base carrying the machine (fixed cylinder); the other is placed in such a way as to allow a side movement away, through a system of sliding guides obtained by milling. The base is made of steel and is constituted by a double frame which confers to the mill remarkable rigidity, allowing a lamination of high quality.

Cylinders are mounted on these our models are kept under pressure by special hydraulic pistons that allow the cylinder to be able to detach if entered the hard bodies (type stainless steel) which is not retained by the magnets in order to protect the surface of the cylinders.

These hydraulic cylinders, moreover, allow to obtain the self-regulation of the thickness of the rolled product in function of the hourly production, adjustable by means of a guillotine-type shutter which feeds a distributor cylinder rotating lined, located in such a way as to distribute the cereals on the entire width of the rolling cylinders, so as to be hardly clogged with foreign bodies (Stones, etc …).

The structure is also constructed so as not to allow storage of cereals and in such a way as not to leave the corners are dirty.

Hydraulic System, feedback control of the pressure commissioning and electronic display. This system allows the operator to check the thickness of the mill during the crushing with an accuracy of 0.10 mm.

The advantages:

- Electronic adjustment of the final thickness of flakes

- Pressure supply to electronic control

- Easier adjustment of the distance between the rollers

- Possibility to adjust the distance of the rollers during operation

- Setting visual inspection always possible, thanks to the dedicated display

- Display Settings for visual inspection

- Head of unit full of solenoid valves and systems for pistons of guide

- The two encoders

- Keyboard

- Liters of hydraulic oil units are 90 liters

The scrapers of the cylinders are pressed with hydraulic cylinders. The material of scrapers is steel super-fast (hardened and ground).

This type of system allows the operator to check the thickness during the flaking with an accuracy of 0.10 mm.

The pressure of the piston with calibration.

The system is also able to detect immediately the piston and the roller position: this means a control extremely high. The result is a final product of high quality.

The scrapers of the cylinders are pressed with hydraulic cylinders. The material of the scrapers is steel super-fast (hardened and ground).

The mill in order to ensure a service more convenient and ordinary (cleaning and lubrication monthly), possesses the inspection hatches suitable, with access points of centralized lubrication. The machine is equipped with a system of automatic lubrication of the bearings.

The mills of the series LAM900 are supplied complete with an electric drive to CEI regulations with: counters complete with thermal overload relays for motor control, lock, mushroom red emergency button voltage of the auxiliary circuit 24 VAC and indicator lights for signal of the controlled motors.

The control panel also has a touch-screen display and PLC (Siemens) with the use of the selector for the choice of automatic or manual operation.

For the intervention of the thermal relay, to protect the motors, part the siren of emergency.

Customer reviews

No reviews were found for Model LAM900 - The Mill of Cereals. Be the first to review!